Medium and heavy duty vehicles make up a relatively small proportion of road traffic, yet they present an outsized contribution to air pollution. Around the world, new regulations restricting emissions are being introduced in an attempt to improve air quality and population health, including standards coming into effect in California in 2027 that require all commercial diesel engines reduce oxides of nitrogen (NOx) by 90%.

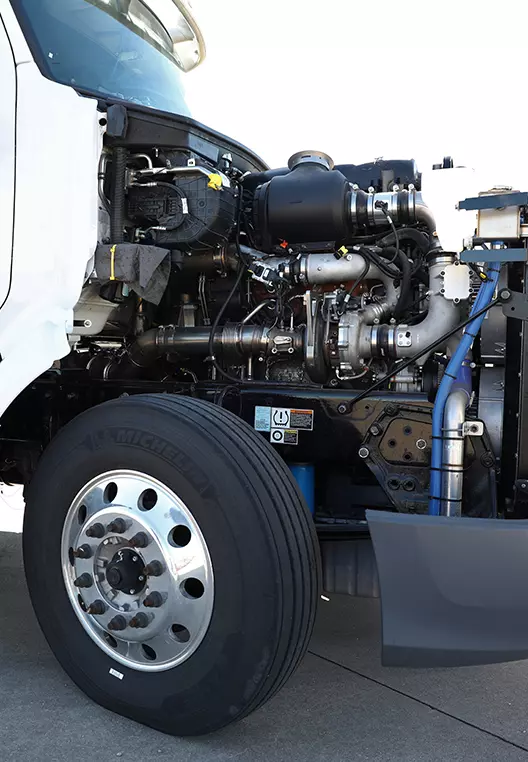

Whilst combustion engines are still required by the demands of long-haul global trade, it is important to cut their emissions as much as possible. Achates Power has developed an opposed piston engine that substantially reduces emissions, whilst remaining suitable for commercial vehicle use. During the transition period needed to establish the energy infrastructure and other changes required for zero emissions, such modifications will help to quickly improve air quality.

Results from the demonstration indicate that the technology would offer broad application, and the ability to meet the California Air Resources Board’s 2027 ultralow NO x regulations by a substantial margin.

Walmart will be piloting the engine in a Peterbilt 579 truck for their California operations later this year, and Achates Power is already working with a group of organizations to commercialize a heavy duty engine for series production in 2027.

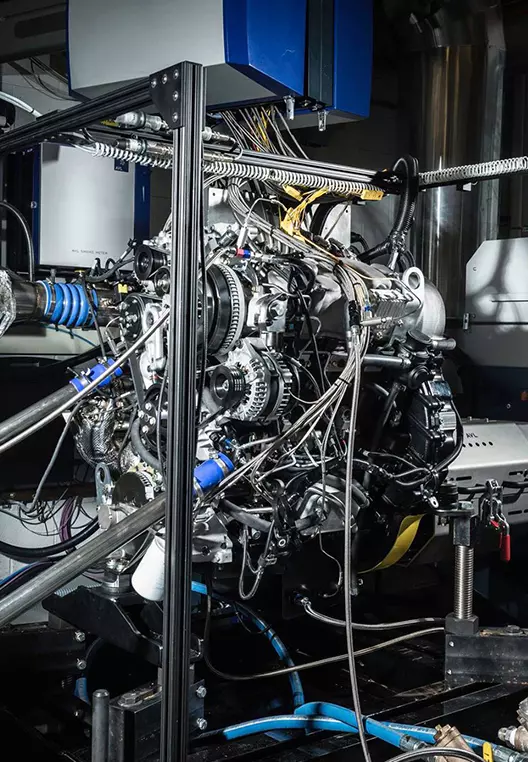

Achates Power successfully built and tested four 10.6L opposed-piston engines for the Heavy Duty Diesel Demonstration Programme, an initiative funded by various agencies in California. Measured results from the demonstrations show the engines achieving a 96% reduction in tailpipe NOx, a 75% reduction in engine-out particle matter compared to benchmark diesel engines, and a 7% reduction in carbon dioxide compared to U.S. regulatory standards.

The results were achieved with conventional, underfloor aftertreatment systems, making them significantly cheaper and less complex than other solutions.