Why We Invested in Energy Robotics

8 October 2025

In our second thought leadership article, we highlighted the convergence of robotics and AI, and the growing role of autonomous systems in hazardous environments. This third article continues the robotics theme by focusing on our new investment in Energy Robotics, a leader in autonomous fleet orchestration and artificial intelligence software.

The Industrial Robotics Inflection Point

The industrial robotics market has reached an inflection point. Across critical infrastructure sectors—Oil & Gas, Power & Utilities, Chemicals, Security, and Defence— operators face a convergence of risks: ageing infrastructure, acute labour shortages, and rising safety and sustainability demands. Traditional inspection methods cannot keep pace.

The inspection challenge is substantial and growing. From offshore rigs to substations, chemical plants to secure perimeters, monitoring and inspection are critical to operational integrity. Many industrial workplaces contain confined or hazardous inspection zones that expose workers to dangerous environments. Meanwhile, more than 50% of grid infrastructure in developed economies is over 20 years old1, creating increased demand for monitoring, inspections, and repairs at precisely the moment when labour, shortages are most acute.

The numbers tell the story: Utilities are among the hardest-hit sectors facing workforce aging in developed economies, with over half of electricity sector workers in countries like the UK being over age 452. In Oil & Gas, 50% of the industry’s workforce will be eligible to retire within the next decade3. These statistics represent a fundamental shift that is driving the industry from pilot robotics programs to operational scale deployment.

Beyond Single-Robot Solutions: The Fleet Orchestration Opportunity

The answer lies in the autonomous orchestration of specialized robot fleets. True value comes from different robots performing distinct tasks: pipe-crawlers for internal corrosion inspections, aerial drones for flare stack surveillance, quadrupeds for navigating complex terrains, and magnetic crawlers for vertical asset monitoring.

This insight is drawn from our experience building a comprehensive methane detection and monitoring portfolio. Our investments in companies such as Insight M (methane emissions identification), GHGSat (industrial greenhouse gas monitoring), SeekOps (drone-mounted emissions sensors), and SensorUp (methane data aggregation), have reinforced our understanding that real value is achieved by engaging throughout the entire value chain: data capture, analysis, contextualization, and decision support. Energy Robotics (ER) is the company that operationalizes this in robotics.

That is why we invested in Energy Robotics. It is a hardware-agnostic orchestration software platform that serves as the “Microsoft for robots,”4 uniquely positioned to benefit from hardware innovations across the entire robotics ecosystem.

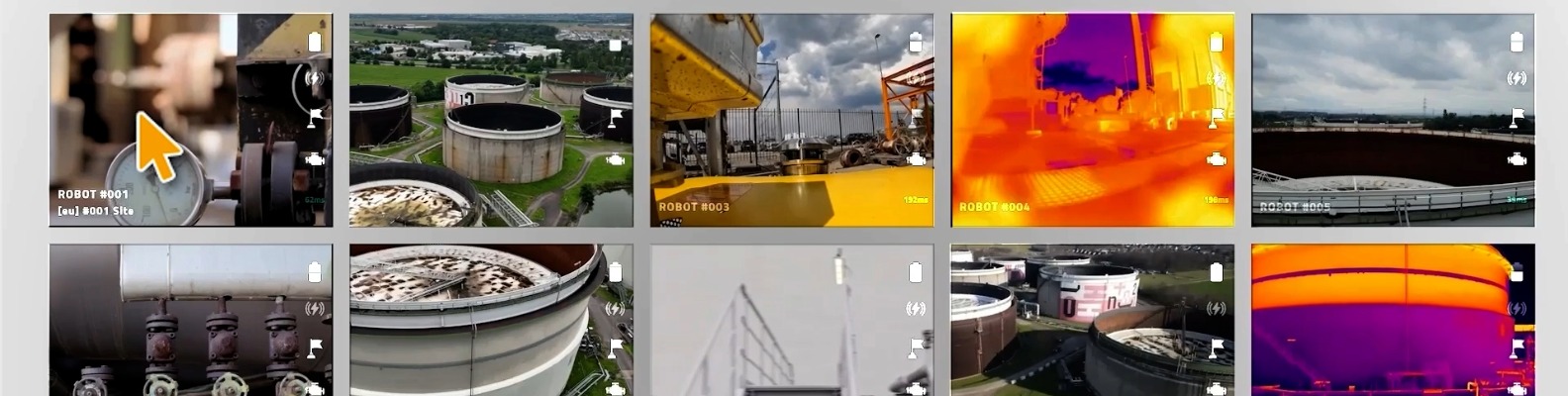

Fleet of industrial robots compatible with Energy Robotics’ software; Source: Energy Robotics

Why Energy Robotics Stands Out

Four key factors convinced us that Energy Robotics has built a leading robotics software platform:

1. Hardware-Agnostic Ecosystem Leadership

Energy Robotics has integrated with 8 robot platforms, including all available ATEX-certified robots for Oil & Gas operations (Boston Dynamics, ExRobotics, Taurob, , and Mitsubishi Heavy Industries). This comprehensive integration creates significant barriers to entry. Any new entrant faces years of integration work on both the OEM and customer sides, while ER provides customers with flexibility and lower costs through larger, mixed fleets without vendor lock-in.

Fleet of industrial robots compatible with Energy Robotics’ software; Source: Energy Robotics

2. Proven Enterprise Traction at Scale

Energy Robotics has executed over 1 million autonomous inspections and saved 32,000+ hours of hazardous human labor across five continents, serving customers such as ADNOC, bp, Repsol, Shell, BASF, Merck and E.ON. Major Oil & Gas players, who have experienced operational cost savings of up to 40%, are now driving procurement requirements rather than testing concepts, demonstrating clear product-market fit across operations.

Sample of Energy Robotics customers; Source: Energy Robotics

3. Vertical Data Platform with AI at the Core

This is not just fleet management. ER’s onboard intelligence interprets sensor data in context—combining thermal, acoustic, gas, and visual streams into actionable insights. Advanced AI models operate directly on the robots’ edge and cloud, delivering fast anomaly detection and contextual interpretation in unstructured environments. The cloud platform then aggregates data across fleets, transforming inspection into a vertically integrated data service: from on-robot perception to enterprise dashboards, Evergreen Digital Twin, and integration with ERP, CMMS, and customer APIs. This full-stack approach creates durable switching costs and compounding value with every mission executed.

Energy Robotics’ software platform allows facility-wide thermal and visual data capture; Source: Energy Robotics

4. World-Class Team with Proven Experience Orchestrating Robot Fleets

The founding team combines deep technical robotics controls expertise (34 RoboCup championships between them) and a specialized background in SLAM (simultaneous localization and mapping) with operational scaling experience.

The Convergence Moment: Why Now?

Several structural tailwinds make this the right moment for autonomous fleet management. Technology maturation has accelerated, with rapid advancements in AI, including vision-language models and edge AI and a 60–80% reduction in sensor and battery costs over the past five years, making autonomous remote operations economically viable. Frontier research points to this combination of high-level reasoning and low-level control as the defining baseline for robotics, and ER has already embedded these principles into its platform.

Energy Robotics has also cleared critical barriers such as cybersecurity integration, GDPR alignment, and ATEX certification, positioning it ahead of competitors – demonstrating enterprise readiness.

Additionally, validated business models are emerging as market adoption of robots grows. Companies are succeeding with varied approaches, from full-stack platforms that optimize hardware-software integration across smaller fleets to hardware-agnostic platforms like Energy Robotics.

Looking Forward: Enabling The Infrastructure of Tomorrow

As a decarbonization investor, we are particularly excited about Energy Robotics’ climate impact potential. Its platform detects emissions through autonomous ground robots equipped with gas sensors, optical imaging, and acoustic cameras to patrol facilities daily. These robots detect methane and other volatile organic compounds (VOC) plumes and SF6 leaks in real-time.

We see a future where critical infrastructure is intelligent, autonomous, digital, and fully orchestrated—leveraging AI and robotics innovations to deliver visibility without exposure, insight without delay, and scalability without increasing headcount. The market is evolving from specialized platform maturation to multi-function integration, ultimately aiming for full autonomy across offshore platforms and normally unattended installations.

With clear opportunities for our Commercialization Team to help accelerate market adoption, we are excited to back Energy Robotics and support their journey as the leader in autonomous fleet orchestration and artificial intelligence software for critical infrastructure.

1IEA, “Electricity Grids and Secure Energy Transitions,” 2023, p. 27.

2Philip Gordon, “The ageing workforce’s brain drain,” Smart Energy International, September 2, 2019, https://www.smart-energy.com/industry-sectors/energy-grid-management/the-ageing-workforces-brain-drain/

3Society for Human Resource Management, “Preparing for an Aging Workforce: Oil, Gas and Mining Industry Report,” SHRM Foundation

4Episode of Connected Workers Podcast, July 30, 2025, https://podcasts.apple.com/us/podcast/robots-and-drones-and-ai-oh-my-ep-22/id1793359650?i=1000719796026